With the ability to transfer electrical energy from a source to a variety of devices and systems, power cables are an essential part of electrical systems. From industrial machinery to household appliances, power cables ensure that devices have the electricity they require to function properly. This article will provide an in-depth understanding of power cables by examining their various types, construction, applications, safety considerations, and much more.

First off, what is a power cable?

One kind of electrical cable made especially for moving electrical power from one place to another is called a power cable. They are employed in many different contexts, including industrial and residential buildings. Depending on the installation location and the quantity of current that the cables must carry, power cables come in a variety of sizes and constructions.

a. Vital Roles for Power Cables

Power cables are essential to electrical systems for a number of reasons, including:

Power Transmission: Moving electrical energy from a source (like a power plant or electrical outlet) to end-use equipment (like appliances, machinery, or lighting) is the main purpose of power cables.

Carrying Capacity Current: Power cables are made to securely handle certain current levels, guaranteeing effective operation without overheating or breaking down.

Protection: To guard against external influences, mechanical strain, and electrical interference, power cables are frequently insulated and protected.

2. Building Power Cords

To fully appreciate the operation and effectiveness of power cables, one must have a thorough understanding of their structure. Power cables are made up of a few essential parts:

Conductors (a)

The conductor, which is the main part of a power cable, is in charge of transporting electricity. Typical materials for conductors consist of:

Copper is the most often used material for power line conductors because of its exceptional conductivity. Because of its great endurance and low resistance, it is perfect for a wide range of applications.

Aluminum: Compared to copper, aluminum is less costly and lighter. Despite having less conductivity than copper, its advantages in weight and cost make it a popular choice for power transmission applications.

b. Insulation

The conductor is encircled with insulation, which stops electrical leakage and guarantees the secure transfer of electricity. Insulation is fabricated from a variety of materials, such as:

Polyvinyl chloride, or PVC, is a material that is frequently used for insulation because it is inexpensive and resistant to chemicals and moisture.

Cross-Linked Polyethylene, or XLPE, is frequently utilized in high-voltage applications due to its exceptional electrical and thermal resistance.

Rubber: Fits for portable power cables since it is flexible and resistant to environmental conditions.

c. Covering

Sheathing, a power cable’s outer covering, offers extra defense against chemicals, moisture, and mechanical harm. Materials for sheathing may consist of:

PVC: Is a common material for indoor applications and provides good protection.

LSZH (Low Smoke Zero Halogen): This type of material is appropriate for use in public buildings and transit systems since it is made to reduce the amount of smoke and harmful gases released during a fire.

d. Armor

Power cables may be armored in some situations to give them additional defense against physical harm. Armor is usually utilized in underground or industrial installations and can be built of materials like steel or aluminum.

3. Power Cable Types

There are numerous varieties of power cables, each intended for a particular use and set of specifications. It is crucial to comprehend these kinds in order to choose the appropriate cable for a certain work.

a. Cables with Low Voltage

Low voltage cables are made to transport electricity at voltages that are normally lower than 1,000 volts. Lighting, small appliances, and home wiring are common applications. Low voltage cable types include:

Flat Cables: Frequently utilized in domestic wiring, flat cables are simple to install in confined areas and have a thin profile.

Round Cables: Round cables are flexible and capable of supporting moderate current loads; they are frequently used for portable appliances and equipment.

b. Cables at a Medium Voltage

Applications requiring power transfer between 1,000 and 35,000 volts employ medium voltage cables. Power distribution systems and industrial environments are common places to find these wires. They are made to resist harsher weather factors and electrical stress.

d. Cables with High Voltage

When transmitting power at voltages more than 35,000 volts, high voltage cables are utilized. They are necessary in substations and power lines for long-distance power transmission. For high voltage cables to be reliable and safe, certain sheathing and insulation are needed.

d. Cables with armor

Armored cables are intended for usage in industrial or subterranean installations, among other places, where extra security is required. The armor offers mechanical defense against shocks and other influences.

f. Adaptable Wires

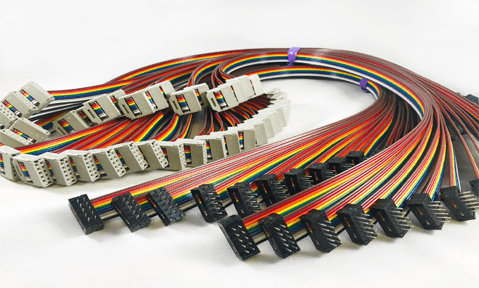

Flexible cables are made for uses requiring bending or movement, including in machinery and portable power equipment. These cables can tolerate repeated twisting and bending because of their sturdy insulation and flexible conductors.

4. Power Cable Applications

Power cables are widely used in many different areas and businesses. The following are a few typical uses:

a. Domestic Electrical

Power cables are used in residential settings to wire electrical systems throughout dwellings. By connecting switches, outlets, lighting fixtures, and appliances, they guarantee that power is delivered safely to the necessary locations.

b. Industrial and Commercial Uses

Power cables are utilized in commercial and industrial environments for HVAC (heating, ventilation, and air conditioning) systems, heavy machinery, and lighting. They need to be strong and able to support heavy current loads.

d. Distribution of Power

In power distribution networks, power cables are essential for moving electricity from substations to final consumers. They are utilized in subterranean and overhead power lines that provide homes, companies, and industries with electricity.

d. Systems of Renewable Energy

Power cables are necessary to link solar panels, wind turbines, and energy storage systems to the grid as the use of renewable energy sources increases. These cables need to be built to withstand a range of voltages and weather.

e. Systems of Transportation

In transportation networks like trains and electric car charging stations, power cables are utilized. They guarantee that electric cars and trains get the power they require to run.

5. Power Cable Safety Considerations

The first focus should always be safety when handling power wires. The following are some crucial safety points to remember:

Appropriate Setup

Proper installation of power wires is essential to avoid electrical risks. This entails utilizing the appropriate kind of cable for the job, adhering to regional electrical laws, and hiring trained specialists for installation.

b. Continual Exams

Power cable checks on a regular basis are necessary to spot possible problems before they get out of hand. This entails looking for indications of deterioration, wear, or overheating.

c. Circuit Breaker Usage

Protecting power connections from overloads and short circuits can be achieved by installing fuses or circuit breakers in electrical systems. When these devices identify a dangerous condition, they automatically cut off the electricity.

d. Adequate Grounding

For electrical systems to operate safely and to prevent electrical shock, power lines must be properly grounded. Grounding gives extra electrical current a safe way to escape.

d. Being Aware of Environmental Elements

Temperature, humidity, and chemical exposure are examples of environmental elements that must be taken into account while choosing and installing power lines. By using cables made for particular circumstances, harm can be avoided and dependability can be guaranteed.

6. New Developments in Power Cable Technology

The creation and design of power cables are changing in tandem with the advancement of technology. In power cable technology, the following are some major trends:

Elevated Attention to Energy Efficiency

Manufacturers are working hard to produce power connections that use less energy because of growing worries about environmental effect and energy use. Enhancing the insulating qualities of cables and minimizing energy loss during transmission are two examples of this.

b. Cable Technologies with Smart Features

Developments in smart technology are impacting power cable construction. A better way to manage systems is to have real-time data for temperature, voltage, and current levels by using sensors built into smart cables.

c. Materials that Are Sustainable

An increasing number of power cables are being built with environmentally friendly and sustainable materials. The production and disposal of cables can be made with less of an environmental impact by using recycled materials and biodegradable insulation.

d. Increased Sturdiness and Adjustment

Power cords’ strength and suppleness are always being enhanced by manufacturers, which makes them more appropriate for demanding situations and mobility-intensive applications. The creation of cables resistant to high temperatures and mechanical strain falls under this category.

7. Selecting the Appropriate Power Cable

To guarantee optimum performance and safety when choosing a power cable for a particular application, the following considerations should be taken into account:

Ratings for Voltage and Current

For your application, select a power cable rated for the right voltage and current. Overloading the cable may cause it to overheat and perhaps fail.

b. The surroundings

Take into account the surroundings in which the power wire is going to be installed. Extremes in temperature, exposure to chemicals or moisture, and the requirement for flexibility are all examples of this.

c. Length of Cable

Choose a power cord that is the right length for the job at hand. It is crucial to select the appropriate length of cable for your requirements as longer cables may result in voltage dips and energy loss.

d. Adherence to Regulations

Verify that the power cable complies with all applicable national and local electrical standards and norms. This contributes to the dependability and safety of electrical infrastructure.

f. Brand Reputation and Quality Invest